Ho leka-lekanya matla a axial ka har'a lipompo tsa centrifugal tse ngata ke theknoloji ea bohlokoa ho netefatsa ts'ebetso e tsitsitseng. Ka lebaka la letoto la li-impellers, matla a axial a bokella haholo (ho fihlela ho lithane tse 'maloa). Haeba e sa leka-lekanngoa hantle, sena se ka lebisa ho jara boima bo feteletseng, tšenyo ea tiiso, kapa esita le ho hlōleha ha thepa. Ka tlase ke mekhoa e tloaelehileng ea ho leka-lekanya matla a axial, hammoho le melao-motheo ea bona, melemo le mathata.

1.Symmetrical Impeller Arrangement (Mokokotlo-Mokokotlo / Sefahleho-le-sefahleho)

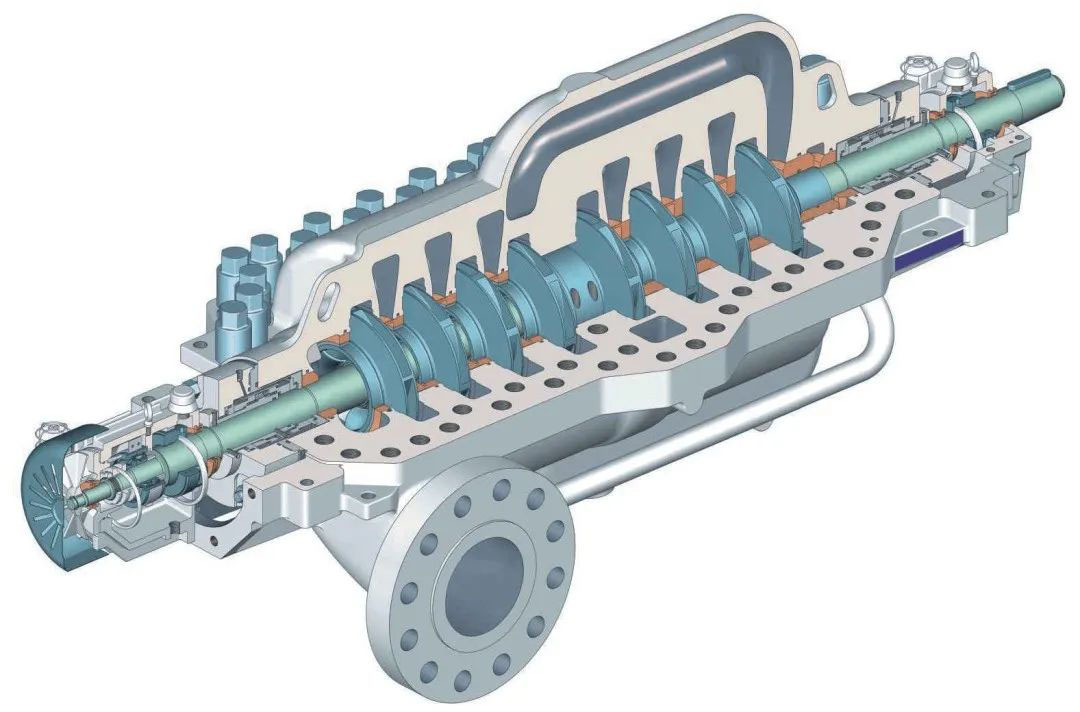

Moralo oa sesebelisoa sa axial force balance ea pompo ea sejoale-joale ea centrifugal, sethala sa impeller se khethoa ka kakaretso e le palo e lekanang, hobane ha sethala sa impeller e le palo e lekanang, mokhoa oa kabo ea symmetrical o ka sebelisoa ho leka-lekanya matla a axial a thepa, 'me matla a axial a hlahisoang ke symmetrically ajoa impeller ka ts'ebetso ea magnide e tla lekana ts'ebetsong ea magnide. boemo ba tekano boemong ba macroscopic. Ha ho etsoa moralo, hoa lokela ho hlokomeloa hore boholo ba ho tiisa throttling pele ho kenngoa ha impeller e ka morao ho lumellana le bophara ba impeller ho etsa bonnete ba ho tiisa hantle.

●Molao-motheo: Li-impeller tse haufi li hlophisitsoe ka litsela tse fapaneng e le hore matla a tsona a axial a hlakole.

●Ho kgutlela morao: Lihlopha tse peli tsa li-impellers li kenngoa ka mokhoa o ts'oanang ho pota-potile bohareng ba pompo.

●Sefahleho le sefahleho: Li-impeller li hlophisitsoe li shebane le ka hare kapa ka ntle ka tlhophiso ea seipone.

●Melemo: Ha ho lisebelisoa tse ling tse hlokahalang; sebopeho se bonolo; ts'ebetso e phahameng ea ho leka-lekanya (ho feta 90%).

●Mefokolo: Moralo o rarahaneng oa matlo a pompo; ho thatafatsa tsela ea phallo; e sebetsa feela ho lipompo tse nang le mekhahlelo e lekanang.

●Lisebelisoa: Lipompo tsa phepelo ea likhatello tse phahameng, lipompo tsa petrochemical multistage.

2. Ho leka-lekanya Drum

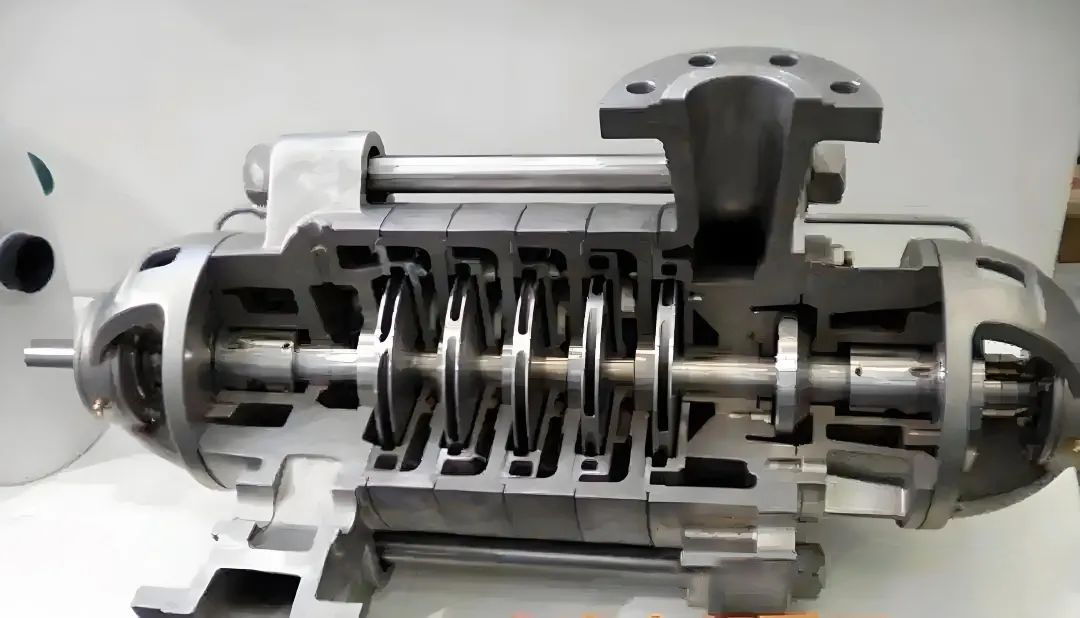

Sebopeho sa drum se leka-lekaneng (hape se tsejoa e le piston ea balance) ha e na sebaka se thata sa axial running clearance, se ka khonang ho lefella boholo ba axial thrust, empa eseng kaofela ha axial thrust, 'me ha ho na matšeliso a eketsehileng ha a tsamaea sebakeng sa axial,' me li-thrust bearings hangata lia hlokahala. Moralo ona o tla ba le phepelo e phahameng ea ka hare (ho lutla ka hare) empa o mamella ho qala, ho koaloa, le maemo a mang a nakoana.

●Molao-motheo: Moqomo oa cylindrical o kenngoa ka mor'a hore ho be le impeller ea mohato oa ho qetela. Mokelikeli oa khatello e phahameng o lutla ka lekhalo pakeng tsa moropa le casing ho kena ka kamoreng e nang le khatello e tlaase, e hlahisang matla a ho loantša.

● Amelemo: Bokhoni bo matla ba ho leka-lekanya, bo loketseng khatello e phahameng, lipompo tse ngata (mohlala, mekhahlelo ea 10+).

●Mefokolo: Litahlehelo tsa ho lutla (~ 3-5% ea tekanyo ea phallo), ho fokotsa katleho. E hloka liphaephe tse eketsehileng tsa ho leka-lekanya kapa mekhoa ea ho potoloha hape, ho eketsa ho rarahana ha tlhokomelo.

●Lisebelisoa: Lipompompo tse kholo tsa centrifugal (mohlala, lipompo tsa lipeipi tsa sebaka se selelele).

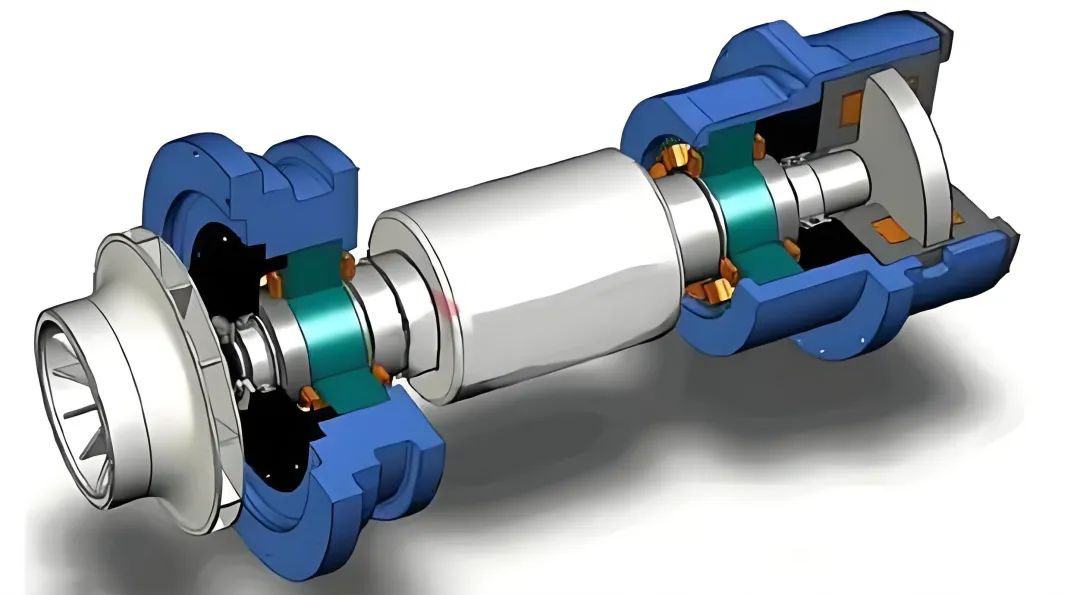

3.Ho leka-lekanya Disk

Joalo ka mokhoa o tloaelehileng oa moralo oa ts'ebetso ea sesebelisoa sa axial force balance ea pompo ea sejoale-joale ea multistage centrifugal, mokhoa oa ho leka-lekana o ka fetoloa ka mokhoa o itekanetseng ho ea ka tlhokahalo ea tlhahiso, 'me matla a leka-lekaneng a hlahisoa haholo ke karolo ea sefapano pakeng tsa ho tlosoa ha radial le ho tlosoa ha axial ea disk,' me karolo e 'ngoe e hlahisoa haholo-holo ke karolo ea axial le karolo ea likarolo tse peli tsa ho leka-lekana. ho leka-lekanya matla a axial. Ha ho bapisoa le mekhoa e meng, molemo oa mokhoa oa ho leka-lekanya poleiti ke hore bophara ba tekanyo ea tekanyo e kholoanyane le kutloisiso e phahameng, e leng ho ntlafatsang botsitso ba ts'ebetso ea sesebelisoa sa thepa ka katleho. Leha ho le joalo, ka lebaka la tumello e nyenyane ea axial e sebetsang, moqapi ona o ka senyeha habonolo le ho senya tlas'a maemo a nakoana.

●Molao-motheo: Ho kenngoa disk e tsamaeang ka mor'a hore ho be le impeller ea mohato oa ho qetela. Phapang ea khatello ho pholletsa le disk e fetola ka matla boemo ba eona ho loantša matla a axial.

●Melemo: Ka tsela e iketsang ikamahanya le mefuta e fapaneng ea matla a axial; bokgabane bo phahameng ba ho leka-lekanya.

●Mefokolo: Khohlano e etsa hore motho a khathale, e hlokang ho nkeloa sebaka nako le nako. E na le kutloelo-bohloko ho bohloeki ba mokelikeli (likaroloana li ka jam disk).

●Lisebelisoa: Lipompompo tsa metsi a hloekileng tsa methati e mengata ea pele (tse butle-butle li nkeloa sebaka ke meqomo e lekanyang).

4.Ho leka-lekanya Drum + Disk Combination

Ha ho bapisoa le mokhoa oa ho leka-lekanya poleiti, mokhoa oa ho leka-lekana oa moropa o fapane ka hore boholo ba karolo ea eona ea throttle bushing e kholo ho feta boholo ba hub ea impeller, ha disc e leka-lekaneng e hloka boholo ba throttle bushing ho lumellana le boholo ba hub ea impeller. Ha re bua ka kakaretso, ka mokhoa oa ho etsa moralo oa moropa oa ho leka-lekana, matla a leka-lekaneng a hlahisoang ke tekanyo ea li-axial plate bakeng sa karolo e fetang halofo ea matla a axial kaofela, 'me boholo ba eona bo ka fihla ho 90% ea matla a axial kaofela,' me likarolo tse ling li fanoa haholo ke moropa o leka-lekaneng. Ka nako e tšoanang, ka mokhoa o itekanetseng ho eketsa matla a ho leka-lekana ha moropa oa ho leka-lekana o tla fokotsa matla a ho leka-lekana a poleiti ea ho leka-lekana, 'me ka tsela e lumellanang fokotsa boholo ba poleiti ea ho leka-lekana, ka tsela eo ho fokotsa tekanyo ea ho apara ea poleiti ea ho leka-lekanya, ho ntlafatsa bophelo ba tšebeletso ea likarolo tsa thepa, le ho etsa bonnete ba hore ts'ebetso e tloaelehileng ea pompo ea centrifugal e mengata.

●Molao-motheo: Moropa o sebetsana le boholo ba matla a axial, ha disk e lokisa matla a setseng.

●Melemo: E kopanya botsitso le ho ikamahanya le maemo, e loketseng maemo a fapaneng a ts'ebetso.

●Mefokolo: Sebopeho se rarahaneng; theko e phahameng.

●Lisebelisoa: Lipompo tsa indasteri tse sebetsang hantle haholo (mohlala, lipompo tse futhumatsang matla a nyutlelie).

5. Thrust Bearings (Axiliary Balancing)

●Molao-motheo: Li-angular ball bearings kapa li-bearings tsa Kingsbury li monya matla a setseng a axial.

●Melemo: Backup e tšepahalang bakeng sa mekhoa e meng ea ho leka-lekanya.

●Mefokolo: E hloka lubrication kamehla; nako e khuts'oane ea bophelo tlasa meroalo e phahameng ea axial.

●Lisebelisoa: Lipompompe tsa mekhahlelo e menyenyane ho isa bohareng kapa lipompo tsa lebelo le phahameng.

6. Moralo oa Impeller ea Habeli-Suction

●Molao-motheo: Mokelikeli oa ho hula habeli o sebelisoa sethaleng sa pele kapa sa bohareng, ho leka-lekanya matla a axial ka ho kena ka mahlakoreng a mabeli.

●Melemo: Ho leka-lekanya ka katleho ha ho ntse ho ntlafatsa ts'ebetso ea cavitation.

●Mefokolo: Ho leka-lekanya feela matla a axial a mohato o le mong; mekhoa e meng ea hlokahala bakeng sa lipompo tsa mekhahlelo e mengata.

7. Hydraulic Balance Holes (Impeller Backplate Holes)

●Molao-motheo: Likoti li chekoa ka mokokotlong oa impeller, ho lumella mokelikeli o phahameng oa khatello hore o khutlele sebakeng sa khatello e tlaase, ho fokotsa matla a axial.

●Melemo: E bonolo ebile e theko e tlase.

●Mefokolo: E fokotsa katleho ea pompo (~ 2-4%).E loketse feela lits'ebetso tse tlase tsa matla a axial; hangata e hloka li-thrust bearings tse ling.

Papiso ea Mekhoa ea ho leka-lekanya ea Axial Force

| Mokhoa | Katleho | Ho rarahana | Litšenyehelo tsa Tlhokomelo | Lisebelisoa tse Tloaelehileng |

| Li-Impellers tsa Symmetrical | ★★★★★ | ★★★ | ★★ | Lipompo tsa maemo a holimo tse nang le khatello e phahameng |

| Ho leka-lekanya Drum | ★★★★ | ★★★★ | ★★★ | Lipompompo tsa mekhahlelo e mengata ea hlooho e phahameng |

| Ho leka-lekanya Disk | ★★★ | ★★★★ | ★★★★ | Mekelikeli e hloekileng, meroalo e fapaneng |

| Drum + Disk Combo | ★★★★★ | ★★★★★ | ★★★★ | Maemo a feteletseng (nyutlelie, sesole) |

| Li-bearings | ★★ | ★★ | ★★★ | Masala a axial force balancing |

| Motsu oa Habeli | ★★★★ | ★★★ | ★★ | Mokhahlelo oa pele kapa oa mahareng |

| Ho leka-lekanya Likoti | ★★ | ★ | ★ | Lipompompo tse nyane tse nang le khatello e tlase |

Nako ea poso: Mar-29-2025

sales@tkflow.com

sales@tkflow.com